Mechanical Department

The Mechanical Department supports the scientific departments of the institute in the development, manufacturing and integration, test and commissioning of ground- and space-based scientific instruments.

The required expertise for conducting these demanding research and development projects builds on the knowledge of the department's mechanics, technicians and engineers, accumulated over years and subject to continuous update and training.

This enables the coverage of a wide range of applications, environmental conditions and sizes of the corresponding experiments. The nature of these experiments reflects the diversity of the institute's scientific departments, encompassing optical instruments (e.g., UV, VIS, etc.), radio wave instruments (e.g., sub-millimetre, etc.), as well as charged particle instruments.

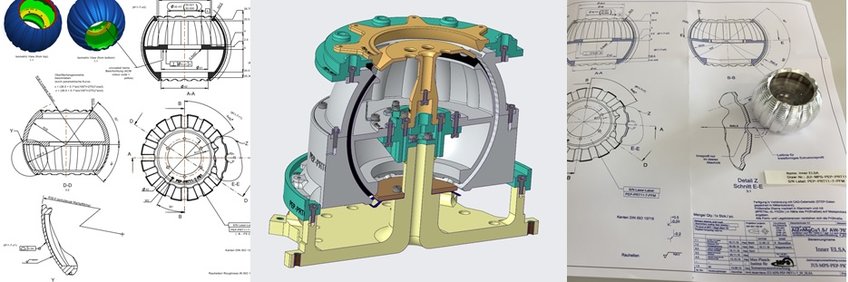

The mechanical development supports instrumental projects of the scientific departments in the areas of design, structural analysis, system engineering, project management, testing and integration.

[more]

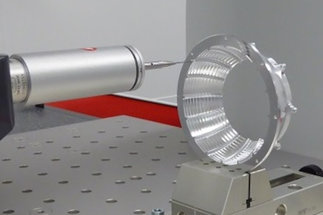

In the precision mechanics workshop, individual components (from prototype to flight parts), small batch series and assemblies are manufactured on state of the art machines, based on technical drawings and 3D CAD data.

[more]

The metal structure workshop supports the instrument development amongst other, in the manufacturing of ground test setups (for vacuum applications) and supporting structures for integration campaigns.

[more]

The quality assurance within the mechanical department is responsible for the dimensional verification, coating/surface treatment and labelling of parts, manufactured in-house or externally, to ensure the required high quality of the products.

[more]

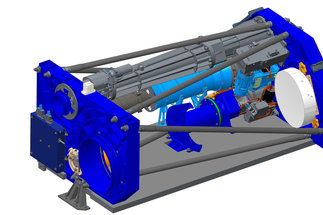

The vibration test facility is covering the structural part of the environmental testing campaigns necessary for scientific payloads on space missions.

[more]

We provide apprenticeships in the professions of industrial mechanic for precision instruments and metal worker for design technology.

[more]